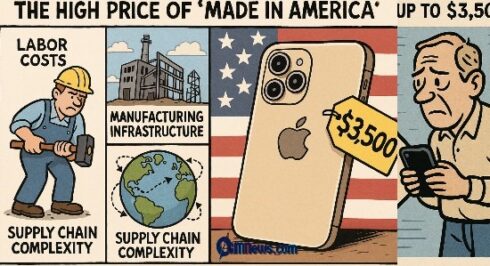

Made in America: The vision of producing iPhones entirely within the United States has gained attention in recent years, especially amid political pressures to strengthen domestic manufacturing and reduce dependence on foreign labor. However, behind the appeal of the “Made in America” label lies a complex web of economic and logistical realities. Experts warn that such a shift would result in significant price hikes for consumers, with estimates ranging from hundreds to thousands of dollars in added costs per device.

This report delves into the critical factors driving the projected cost increases and the wider implications for Apple, consumers, and the U.S. economy.

Made in America: Labor Costs and Manufacturing Infrastructure

One of the most significant challenges in producing iPhones domestically lies in labor expenses. Compared to China and Vietnam, where wages are relatively low and labor is abundant, the United States commands a much higher price tag for skilled and unskilled manufacturing workers. U.S. labor laws, employee benefits, and wage standards further elevate the cost of domestic production.

In addition to labor, the U.S. currently lacks the expansive electronics manufacturing infrastructure that countries like China have developed over decades. Entire ecosystems of component suppliers, toolmakers, and skilled engineers have been built around Apple’s production hubs in Asia. Rebuilding similar infrastructure in the United States would take years, if not decades, and require tens of billions in investment. This lag would not only affect cost but also innovation and speed to market.

Made in America: The Complexity of the Global Supply Chain

The iPhone is not just a product of Apple’s ingenuity—it is the result of a highly complex and interconnected global supply chain. Components for a single iPhone come from more than 40 countries, including semiconductors from Taiwan, camera modules from Japan, and rare earth materials mined in Africa and refined in China.

Made in America: Relocating final assembly to the U.S. would disrupt this finely tuned network. Parts would still need to be shipped internationally, and any delays or disruptions could ripple across the entire production schedule. Experts, including Dr. Rich Swier, argue that while limited relocation of certain production elements might be possible, shifting the entire supply chain to the U.S. is currently impractical and economically inefficient.

Made in America: Estimated Price Increases for Consumers

If Apple were to fully produce iPhones in the U.S., consumers would almost certainly bear the financial burden. Dan Ives of Wedbush Securities estimates that fully American-made iPhones could carry a retail price tag of $3,500—more than triple the cost of a current base model.

Other analysts echo similar concerns. Barton Crockett from Rosenblatt notes that even tariffs alone—without complete domestic production—could drive a 40% price increase. This would raise the base model from $799 to $1,142 and push high-end models to nearly $2,300. Meanwhile, Bank of America Merrill Lynch projects that moving just 10% of assembly to the U.S. could result in an 8% hike, while a 50% relocation would cause prices to rise by 14%. These numbers paint a sobering picture of what domestic iPhone production could mean for American consumers.

Made in America: Tariffs and the Ongoing Trade Tensions

Trade policies have already begun to impact Apple’s supply chain. A recent 104% tariff imposed on key Chinese imports has sent shockwaves through the tech industry. For Apple, which depends heavily on Chinese manufacturers like Foxconn, such tariffs could drastically inflate production costs.

Some consumers are responding by rushing to purchase iPhones before potential price hikes take effect. Meanwhile, Apple has remained largely silent on whether it will absorb these additional costs or pass them directly to buyers. The uncertainty has only heightened concerns about affordability and access, particularly as new iPhone models are released.

Made in America: Strategic Risks to Apple’s Market Position

Apple’s global success hinges in part on its ability to maintain competitive pricing while offering premium quality. A dramatic increase in iPhone prices could weaken Apple’s edge, especially in emerging markets where affordability is a key factor. Companies like Samsung and Xiaomi could gain ground if Apple is forced to significantly raise prices in the U.S. and abroad.

Moreover, a pivot to American manufacturing would force Apple to rethink its business model. Its just-in-time manufacturing philosophy, which relies on proximity to suppliers and high-speed logistics, would be compromised by geographic and systemic shifts. Strategic missteps in this area could result in product delays and consumer dissatisfaction.

Made in America: The Political and Economic Motivation for U.S. Production

Despite the challenges, there are growing political and economic pressures for Apple to repatriate at least part of its manufacturing. Proponents argue that doing so would create high-paying jobs, bolster the domestic tech industry, and reduce dependence on geopolitical rivals like China.

However, these goals come at a steep price. The U.S. would need to offer significant incentives, such as tax breaks and federal subsidies, to make domestic manufacturing viable for Apple. Without such support, companies are unlikely to make the transition voluntarily. For now, partial onshoring or hybrid production models seem more realistic than a full domestic overhaul.

Made in America: A Balancing Act Between Patriotism and Practicality

The idea of American-made iPhones is compelling, especially amid concerns about global supply chain vulnerability and economic independence. Yet, the reality is far more complex. Higher labor costs, insufficient infrastructure, and the fragile balance of a global supply network make full domestic production a costly and disruptive proposition.

Made in America: In the end, Apple and its consumers are caught in a balancing act between patriotic ideals and economic practicality. While partial shifts in production may help appease political demands, the dream of a fully U.S.-made iPhone remains—at least for now—an expensive one.